TECHNICAL DATA

REFERENCE

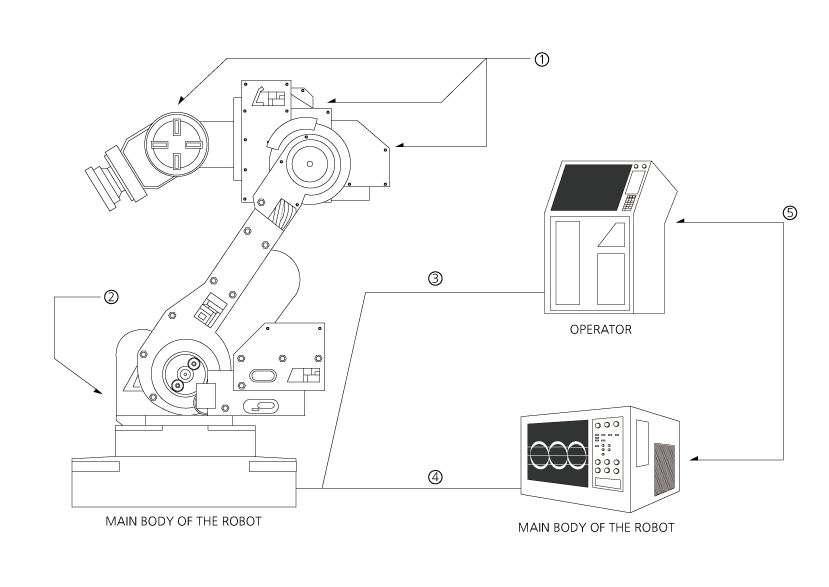

Application Part of Robotics Cable

Uses and Characteristics for each part

| Application Part | Uses | Characteristics | Recommendation Model | |

| 1 | Signal | Super Flexible | High Speed, It performed many repeated movements | KIFLEX RFHV, KIFLEX RFHVU |

| Power | Super Flexible | KIFLEX RFHV, KIFLEX RFHVU | ||

| 2 | Signal | High Flexible | Medium Speed, It performed many repeated movements. | KIFLEX RFHV - SB, KIFLEX RFHVU - SB |

| Power | High Flexible | KIFLEX RVV, KIFLEX RFHV | ||

| 3 | Signal | Flexible | Low Speed, Lead for controlling the operation. | KIFLEX RVV - SB |

| 4 | Signal | Flexible | Assumes using a cable suitable for the purpose of each part of a connection cable of each operating equipment into portions with a fixed part and movement. | KIFLEX RVVU, KIFLEX RFHVU |

| Power | Fixed | KIFLEX RVV, UL2464, UL2969 | ||

| Power | Flexible | KIFLEX RVVU, KIFLEX RFHVU | ||

| Power | Fixed | KIFLEX RVV, VCT, CVV | ||

| 5 | Signal | Fixed | Assumes the use of wires and cables used for internal control device. | PVC Insulation Wire & Cable |

| Power | Fixed | PVC Insulation Wire & Cable | ||

REFERENCE

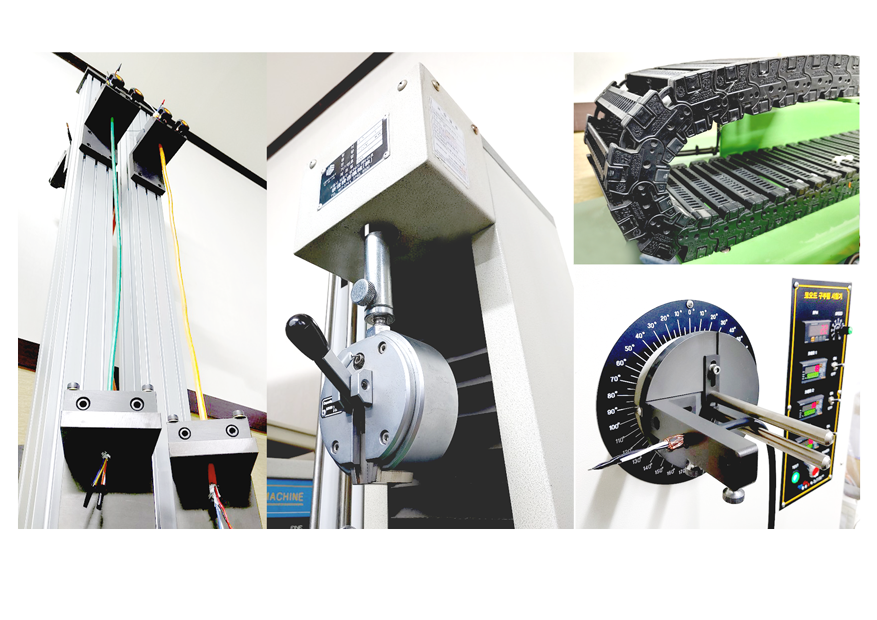

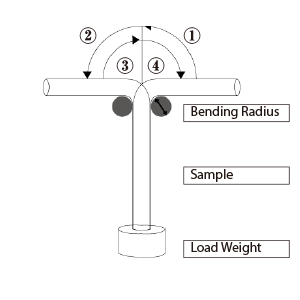

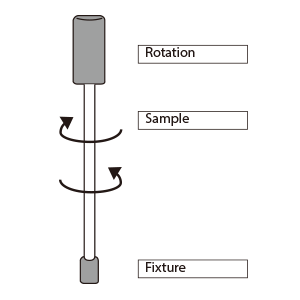

Reliance of the Robotics Cable

| Item | 90° Left & Right Bending Test | U-Bending Test | Torsion Test |

| Condition | Bending Radius : Cable Diameter X 10 | Bending Radius : Cable Diameter X 7.5 | Torsion angle : ±90°, ±180°, ±360° |

| Load Weight : 500g | Speed : 40 Cycle/min | Load Weight : 250g | |

| Speed : 40 Cycle/min | Acceleration : 2G (20㎨) | Speed : 60 Cycle/min | |

| Cycle : ①→②→③→④ | Stroke length : 1200mm | Stroke length : 1000mm | |

| Movement |  |  |  |

| Data | Fixed Type : 100,000 Cycle | Fixed Type : 600 Cycle | Fixed Type : 1000 Cycle |

| Flexible Type : 2,000,000 Cycle | Flexible Type : 8,000,000 Cycle | Flexible Type : 2,000,000 Cycle | |

| High Flexible Type : 10,000,000 Cycle | High Flexible Type : 15,000,000 Cycle | High Flexible Type : 1,000,000 Cycle |

REFERENCE

General Characteristics of

Insulation & Sheath Materials

| Material | PVC Type | Polyethylene type | Poly- Propylene | Fluorine Type | ||||||

| PVC | Heat Resistance PVC | Cross- linked PVC | Poly- ethylene | Cross- linked Poly- ethylene | Ethylene- tetra Fluoro- ethylene | Fluoro- ethylene Propylene | Poly- tetra Fluoro- ethylene |

|||

| Symbol | PVC | H-PVC | XLPVC | PE | XLPE | PP | ETFE | FEP | PTFE | |

| Electrical | Dielectric Strength (kV/mm) | 20 ~ 35 | 20 ~ 35 | 20 ~ 40 | 35 ~ 50 | 35 ~ 50 | 35 ~ 50 | 20 ~ 35 | 15 ~ 30 | 20 ~ 30 |

| Volume Resistivity (ℓ /cm) | 10^12 ~ 10^15 | 10^12 ~ 10^15 | 10^18 | 10^18 | 10^18 | 10^18 | 10^16 | 10^18 | 10^18 | |

| DielectricnConstant | 6 ~ 8 | 6 ~ 8 | 3.5 | 2 | 2.3 | 2.3 | 2.6 | 2.1 | 2.1 | |

| Dielectric Power Factor (%) | 4 ~ 12 | 4 ~ 12 | 3 ~ 10 | 0.02 ~ 0.05 | 0.02 ~ 0.05 | 0.02 ~ 0.05 | 0.2 | 0.03 | 0.02 | |

| Physical | Tensile Strength | 1.0 ~ 2.5 | 1.0 ~ 2.5 | 1.5 ~ 3.0 | 1.2 ~ 1.5 | 1.2 ~ 1.5 | 2..5 ~ 1.5 | 6 ~ 7 | 6 ~ 7 | 1.5 ~ 3.0 |

| Elongation | 100 ~ 400 | 100 ~ 400 | 100 ~ 300 | 500 ~ 700 | 200 ~500 | 500 ~ 700 | 200 ~ 300 | 100 ~ 300 | 100 ~ 300 | |

| Specific Gravity | 1.25 ~ 1.40 | 1.25 ~ 1.40 | 1.25 ~ 1.40 | 0.92 ~ 0.95 | 0.92 ~ 0.95 | 0.89 ~ 0.90 | 1.7 | 2.2 | 2.2 | |

| Softening Temperature(℃) | 120 | 150 | - | 105 ~ 115 | - | 160 | 270 | 285 | 327 | |

| Rated Temperature(℃) | 60 | 75 ~ 105 | 105 | 75 | 75 ~ 105 | 105 | 150 | 200 | 250 | |

| Flame Retardant | Very Good | Very Good | Very Good | Unsatis- Factory | Unsatis- Factory | Unsatis- Factory | Excellent | Excellent | Excellent | |

| Heat Resis- tance | Aiging Resistance | Fair | Good | Very Good | Good | Very Good | Very Good | Excellent | Excellent | Excellent |

| Heat Deformation Resistance | Fair | Fair | Excellent | Very Good | Very Good | Good | Excellent | Excellent | Excellent | |

| Cold Resistance | Fair | Fair | Fair | Very Good | Very Good | Fair | Excellent | Excellent | Excellent | |

| Weather Resistance | Excellent | Excellent | Excellent | Unsatis- factory | Unsatis- factory | Unsatis- factory | Excellent | Excellent | Excellent | |

| O-Zone Resistance | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent | |

| Oil Resistance | Good | Good | Good | Good | Excellent | Excellent | Highly Excellent | Highly Excellent | Highly Excellent |

|

| Acid Resistance | Excellent | Excellent | Excellent | Excellent | Excellent | Good | Excellent | Highly Excellent | Highly Excellent |

|

| Alkali Resistance | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent | Highly Excellent | Highly Excellent |

|

REFERENCE

Identification of Insulation Color

Core Cable

| Core | Color |

| 2C | White, Black |

| 3C | White, Red, Black |

| 4C | White, Red, Green, Black |

| 5C | White, Yellow, Red, Green, Black |

| 6C | White, Yellow, Red, Green, Blue, Black |

| 7C | White, Brown, Yellow, Red, Green, Blue, Black |

| 8C | White, Gray, Yellow, Red, Brown, Green, Blue, Black |

| 9C | White, Gray, Yellow, Orange, Red, Brown, Green, Blue, Black |

| 10C | White, Gray, Yellow, Orange, Red, Brown, Green, Blue, Purple, Black |

| 11C | White, Gray, Yellow, Orange, Red, Brown, Green, Blue, Purple, Black, Pink |

| 12C | White, Gray, Yellow, Orange, Red, Brown, Green, Blue, Purple, Black, Pink, Light Blue |

| 13C | White, Gray, Yellow, Orange, Red, Brown, Green, Blue, Purple, Black, Pink, Light Blue, Light Green |

| 15C | White, Gray, Yellow, Orange, Red, Brown, Green, Blue, Purple, Black, White/Red, Yellow/Red, Red/White, Green/White, Blue/White |

| 20C | White, Gray, Yellow, Orange, Red, Brown, Green, Blue, Purple, Black, White/Red, Gray/Red, Yellow/Red, Orange/White, Red/White, Brown/White, Green/White, Blue/White, Purple/White, Black/White |

| 25C | White, Gray, Yellow, Orange, Red, Brown, Green, Blue, Purple, Black, White/Red, Gray/Red, Yellow/Red, Orange/White, Red/White, Brown/White, Green/White, Blue/White, Purple/White, Black/White, White/Blue, Yellow/Blue, Red/Yellow, Green/Yellow, Blue/Yellow |

| 30C | White, Gray, Yellow, Orange, Red, Brown, Green, Blue, Purple, Black, White/Red, Gray/Red, Yellow/Red, Orange/White, Red/White, Brown/White, Green/White, Blue/White, Purple/White, Black/White, White/Blue, Yellow/Blue, Red/Yellow, Green/Yellow, Blue/Yellow, White/Green, Yellow/Green, Red/Green, Green/Red, Blue/Red |

Pair Identification – 6 Pair

| Core | Color | Core | Color | Core | Color |

| 1P | White + Black | 3P | Yellow + Blue | 5P | Orange + Purple |

| 2P | Red + Green | 4P | Gray + Brown | 6P | Pink + Light Blue |

Pair Identification – 7 Pair

| Core | Color | Core | Color | Core | Color |

| 1P | White + White/Red | 6P | Blue + Blue/White | 11P | Pink + Pink/Black |

| 2P | Yellow + Yellow/Red | 7P | Black + Black/White | 12P | Light Blue + Light Blue/Black |

| 3P | Red + Red/White | 8P | Gray + Gray/Red | 13P | Light Green + Light Green/Black |

| 4P | Brown + Brown/White | 9P | Orange + Orange/White | 14P | Light Gray + Light Gray/Black |

| 5P | Green + Green/White | 10P | Purple + Purple/White | 15P | Light Purple + Light Purple/Black |

REFERENCE

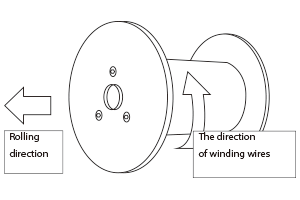

Installing Information

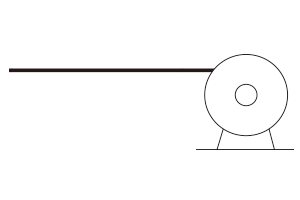

| Shipment Precautions | |||

| · Typically, Wires and cables requires special attention because of weak line when the physical impact of the exterior · If the drum is used fork lifts, and do not drop, and roll if you are careful to load in order not to shock rather than throw by default. |  |

||

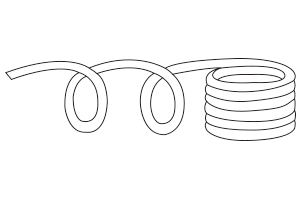

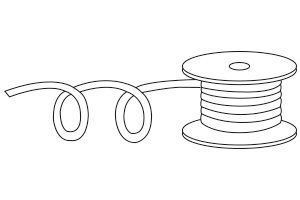

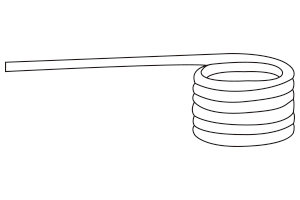

| Way to release the wire | |||

| : This phenomenon must be twisted does not occur. | |||

| Case 1 : Roll Product | Case 2: Drum Product | ||

| 1. Wrong |  | 1. Wrong |  |

| 2. Correct |  | 2. Correct |  |

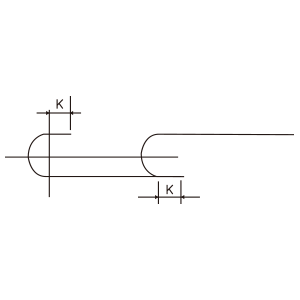

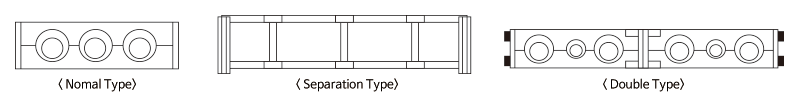

| Install of Cable Track | |||

| 1) The Cable weight should be distributed symmetrically across the width of the chain. 2) When cable diameter is no more than 50% of chain inner height, separation must be made. 3) The free space for the cables in the guide stay should be 20% of the cable diameter. |  |

||